KATSANA® Orbital Platform – Connecting Industrial Sensors to Cloud

Providing operational visibility for critical industrial applications

KATSANA® provides industrial operations achieve real-time visibility and automate day-to-day reporting for the digital age. Take the leap into future of industrial operations by connecting existing and new sensors to KATSANA Orbital Platform. Talk to our enterprise operation consultants to unlock greater value from your operation.

Industry: Cold Chain Operation

Full visibility of cold chain operation from Cold Room to Logistical tracking of Reefer trucks, to delivery of products to customers.

Real-time Cold Room Monitoring & Alerts

Retrieve real-time status of Cold Room temperature, door opening alerts, temperature alerts when it exceeds threshold, and other configurable alerts.

Reefer Truck Temperature Monitoring

Monitor real-time temperature of reefer/distribution trucks with multiple sensors in different compartments. Get historical temperature data, including actual vehicle location for improved accountability.

Instant alerts

Receive immediate alerts for critical incidents such as vehicle movement, high speed, fuel theft and others. Alerts are sent to mobile apps, platform, or email.

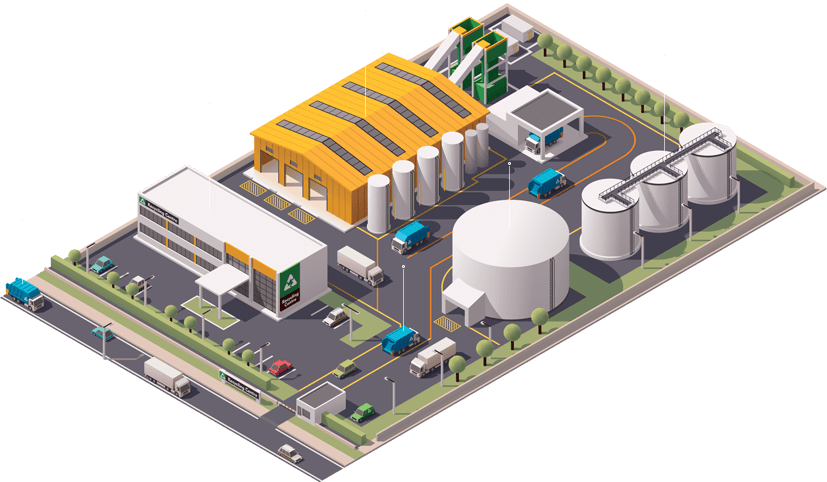

Industry: Estates & Plantations

Bring Estates and Plantation operations to the 21st century. Get automated reports from tanks, machines and other assets in the plantations.-

SKID tank monitoring

Real-time & On-demand liquid level reading for purchasing planning and dispatching from fuel vendors. Eliminate field officer movement to manually check storage capacity. -

CPO Bulk/Static Tank/Main Storage Tank Monitoring

Automating and digitalising records of inventory-receiving procedures, ensuring detection of fuel pilferage or missing fuel usage records. -

Centralised Fuel Management Platform

A single platform for fuel management, reading from multiple sensors across multiple assets in multiple plantations.

Industry: Energy & Power Grid

DriveMark® technology scores driver behavior on the road, allowing you to identify risky drivers for improvements, and potentially reward safer drivers in your fleet.-

Driver and vehicle safety ranking

Each travel taken by the driver and vehicle is scored using DriveMark® algorithm. -

Fleet KPI & Safety Score

Each fleet is scored based on the behavior of vehicles within it, allowing you to set a strong KPI for your fleet managers to achieve. -

Driver coaching through mobile app

Train drivers to become safer on the road by enabling them to see behavior score in real-time and review performance against safety benchmarks.

Industry: Public Works & Utilities

KATSANA® Orbital connects existing sensors in Water Treatment Plants and make them available on the Cloud. Additional sensors can also be added to give better understanding of your plant operation. <-

Reservoir Level Monitoring

Get real-time reading of water level in reservoirs, including past historical data available on web-based interface & smartphones. -

Water Pump Monitoring & cautionary alerts

Get real-time reading on pump performance and critical components such as water pressure, water flow, and pump vibration. -

Water Quality Monitoring & Analytics

Get real-time reading of water treatment plant data such as Water Quality, Level, Pressure, and Flow.

-

Communication & IoT Sensors

KATSANA Orbital communicates over numerous communication medium such as the trusty 2g/3G network, to the power-efficient LoraWAN/Sigfox channels. -

Telco: 2G/3G/LTE

KATSANA IoT Hub supports LTE with 2G/3G fallback in areas with no LTE coverage. -

IoT: LoraWAN/Sigfox

For areas with no telco/GSM coverage, dedicated LoraWAN network can be established as communication backbone for industrial sensors to Cloud. -

Local: WiFi/Ethernet/BLE/RFID

KATSANA IoT Hub can also be configured to tap into existing Wifi/Ethernet communication channel, available on client’s premise. -

Existing Sensors

Connect readouts from existing sensors in your plants to KATSANA Orbital platform without having to invest in new sensors. -

Temperature Sensor

Detects an environment’s ambient temperature and be alerted when the temperature drops or exceeds certain thresholds. -

Vibration Sensor

Detects vibration on machines & engines, allowing pre-emptive repairs to be made before major issues occur. -

Environmental Sensors

Gather environmental data such as humidity, temperature, volatile organic compounds (VOCs), particulate matter (PM2.5), CO2 and others.

Ready for KATSANA® Orbital?